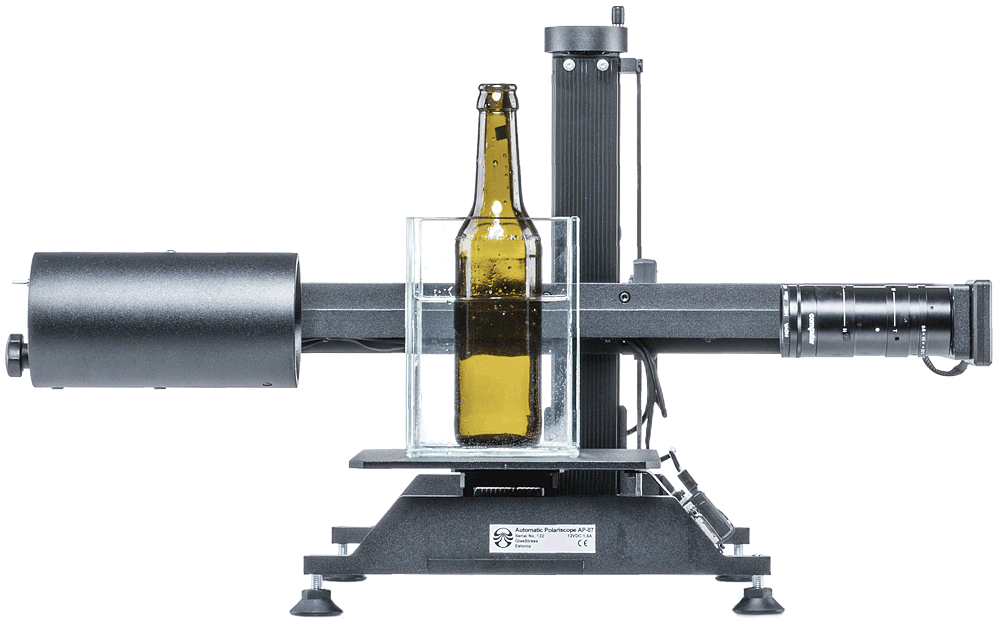

AP-07

Automatic Transmission Polariscope

AP-07 is a computer controlled device designed for automatic stress measurement. Modern integrated photoelasticity algorithms are used for stress calculation from the measurement data. The polariscope can be used for stress measurement near the production line. Its handling does not need any knowledge about photoelasticity or stress analysis. The polariscope is delivered together with a software to control the measurements.

Polariscope AP-07 is a computer controlled device designed for automatic stress measurement in solid and hollow axisymmetric glass products (drinking glasses, bottles, neck tubes of CRT bulbs, lamps, optical fibre preforms, etc.). It permits also edge stress measurement in glass plates and automotive glazing, thickness stress measurement in strips cut out from glass plates, and measurement of stress at edge corners. Photoelastic measurements are completely automatic and take from 2 to 15 seconds. After that stress distiribution in any section of the test object can be displayed on the screen. Diameter of the field of view is 40 mm. The measurement area can be easily displaced using the coordinate device with digital readout. Modern integrated photoelasticity algorithms are used for stress calculation from the measurement data. The polariscope can be used for stress measurement near the production line. Its handling does not need any knowledge about photoelasticity or stress analysis. The polariscope is delivered together with a laptop computer and software to control the measurements.

Stress measurement in axisymmetric specimens is carried out in index matching immersion liquid by passing the light through the specimen tangentially. Three methods of integrated photoelasticity can be used for stress determination:

numerical handling of the fringe pattern (in case of high birefringence),

the phase-stepping method (in case of low birefringence),

the onion-peeling method (for stress measurement in optical fibre preforms and in other cases when stress distribution is discontinuous).

For stress measurement in flat glass and in articles of complicated shape there are four options:

measurement of the edge stresses,

measurement of the arbitrary 2D stress field,

measurement of thickness stresses in strips cut out from glass plates,

measurement of stresses at edge corners and on the surface.

Specifications

Overall dimensions (L*W*H): 660 x 430 x 430 mm

Weight: 11 kg

Communication interface: USB2.0

Power supply: 9 Vdc

Power consumption: 0.8 A

Light source wavelength: 627 (+ optional 530) nm

Sensor resolution: 992*680 pixels

Coordinate device travel range: 200×200 mm

Coordinate device load capacity: 10 kg

Software: GlasStress data capture and calculation software for PC

Software requirements: Windows XP/7/8/10

Polariscope type: Transmission polariscope using integrated photoelasticity

Measurable glass: Axisymmetric hollow and solid glasses, strips

Maximum field of view: 40 mm

Measurement time: 20 seconds

Precision: 5 %

Limitations: Measurements must be made in immersion liquid

Operating conditions: +10 … +50 C

Humidity: 0 – 90 % R.H. (non-condensing)

Ambient light: Direct sunlight must be avoided

Calibration: Calibrated only by manufacturer

Warranty: 2 years